The Holy Cows get the honor of being of our first team with two mentors featured on our blog. We have already highlighted their lead mentor Jon Jack and this week we’re are featuring another of their mentors Kiet Chau. Kiet has been around FRC since 2004 and has grown up in the program. He’s now an engineer with Qualcomm. Read further for the story of how FRC got him his current job, some great stories including some really quick robot rebuilding, and a lot more.

[Responses from July 22, 2013]

CD Username: kiettyyyy

Current Gig/Job: Senior Engineer at Qualcomm Labs

Alma Mater/Degree: University of California, Riverside –

Computer Engineering

Current Team(s): 1538, The Holy Cows (2010-Present)

Former Team(s): 968, Robotics Alliance of West Covina

(2005-2011)

Location: San Diego, CA

Hobbies: Flying, Tinkering, and building robots

I’m extremely honored to be selected as an interviewee for this project. I’m not sure if there’s much that’s special about me, but, we’ll leave that for you to decide.

I started on FRC 968, Robotics Alliance of West Covina in the fall of 2004. I was a very poor student that didn’t care much for school. My mentor, Travis Covington, really helped me turn myself around. I wasn’t really involved in the hard core design work of a FRC robot until 2007. Until then, I was primarily involved in software development. RAWC did not have any software mentors. I came into the program knowing very little C and Basic. Fortunately, the time that I spent driving the robot around to debug/test new control schemes allowed me to become the base driver in 2006. I drove the base of our robots on Einstein in 2006 and 2008. I finally graduated from High School and started attending classes at University of California, Riverside in the fall of 2008.

During the 2009 FRC season, I led the team on all fronts and became the drive coach. I was heavily involved in mechanical design, fabrication as well as team logistics. Eventually, I tagged along with The Holy Cows in 2009 after becoming great friends with Jon Jack. Working in San Diego during the summers eventually pulled me in as a mentor with the team when I was offered a full time position.

When I’m not working on robots, I’m usually tinkering with stuff or flying my Cessna 172 with my girlfriend, Helen (another 1538 mentor) to really cool places. I earned my private pilot certificate September of last year and received my single engine instrument rating a few weeks ago. I’m currently working on my multi-engine rating. I love to fly.

What inspired you to do what you do? Tell us a story.

As a kid, I was always taking apart household items just to see what’s inside. I loved to continue to challenge myself. My dad introduced me to computers at a very young age and got me started with computer networking using token ring networks. At this point, I just loved computers and wanted to be one of those guys who got to put awesome computing devices in every day places. At the beginning of my sophomore year in high school, I decided that I wanted to create a game server hosting company, Vivid-Hosting. This business eventually turned into an internet transit company that caters to small to medium sized businesses in the Los Angeles area. After playing the role of systems admin / network engineer at many companies including my own, I figured that I wasn’t challenged and wanted more. At that point in time, I started to put in a significant amount of effort into 968 as their programming student.

What is your day job, and how’d you get there?

It was my senior year on 968 at the San Diego Regional. Earlier during the build season, in addition to working on the robot, I came up with a scouting platform that was a web application which was viewed on an iPod/iPhone. It did a bunch of cool stuff in terms of generating scouting information that was super crucial for the successful outcome of a match. It happened to be that my mentor, Travis Covington, had demoed it to our regional director who eventually mentioned it to a VP of engineering at Qualcomm. This VP asked me to interview for an internship position at their research and development division in San Diego. I interviewed and was selected for the position.

I began my career at Qualcomm in 2008 at their Corporate Research and Development group working on cellular base stations for LTE. Eventually, I moved onto another project which worked on neuromorphic computing for another 3 years where I was designing and building robots for my day job! During the winter of 2011, just before I was going to return to school, Qualcomm offered me a full time position as a Senior Engineer. I’m still attending class to complete my Bachelors of Science degree.

Just recently, I moved to another division called Qualcomm Labs, which is an incubation engine within Qualcomm to pursue research and development projects that are very short term. Basically, I get to build really cool things very often J

What is your favorite story to tell about robotics?

It’d probably be the one where I learned a lot about listening to much greater mechanical design minds J

While on 968 in 2011, just 2 days before the San Diego Regional, we finally completed our practice robot. It was relatively simple, a single jointed arm with a roller claw that telescoped inside of another tube. Unfortunately, I designed the arm to have a long lever that was some box extrusion to be welded onto the surface of some round 3” tubing. There was no support to transfer the torque between the sprocket mounted to the side of the tubing with welded inserts. We just finished writing our main control software while the students practiced for the event. I happened to be on the phone talking with Jon Jack on The Holy Cows about our robot and possibly sketchy arm. I heard a loud high pitched ping and said “I think that loud noise was our arm… I’ll call you back”. Sure as hell, the arm snapped at the weldment. It was about 10PM and I had class the next morning.

During the next 6 hours, I designed a tube that was an insert for the first stage of the telescope and modified the round tubing so that it’d mate with the insert. That way, the torque would not have to be transferred via a few weldments, but, a pressed fitted tube and weldment.

A couple of the mentors and I went to the high school and began fabricating the round tube with some really, really ghetto tools. Keep in mind, 968 does NOT have a CNC mill to work with at its shop. After getting the tube made, we prepped some materials for me to take to Riverside before class to get made.

After class, I picked up our new inserts and headed on down to a sponsor, Ride and Show (the folks who made the monorail at Disneyland) to get the new arm welded. After getting the arm welded in a matter of an hour or so, I drove the arm down to our powder coat sponsor in Brea for a quick turn.

We picked up the part on the way to the regional and carried it in with our parts allowance. It worked well!

Best part? All of the folks who knew we had a broken arm on our practice robot could not figure out how we managed to get a newly designed and fabricated arm, complete with powder coat done in less than 48 hours before a regional. It was an impressive feat.

What’s your favorite robot that you didn’t help build?

It’s 254’s 2011 robot. This team is the epitome of engineering elegance. Every single part and component is designed with performance and aesthetics in mind. I mean, have you looked at their tube grabber gearbox? Aside from the mechanical stuff, the software was awesome! You can’t have a good robot that just has a great drivetrain and game piece manipulator, you have to have good software!

What apps/software/tools can’t you live without? (Work/Robotics/Home)

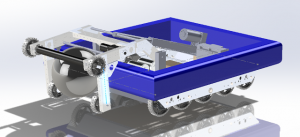

I do all of my mechanical CAD work in Solidworks. I do the majority of my board design work in Cadence and occasionally in Eagle when I’m at home. My go-to software development IDE (integrated development environment) is Visual Studio when I get to develop in Windows environments. When I have to develop for *nix or Mac OS X, I typically use Vi as my editor.

What’s your workspace setup like? (Work/Robotics/Home)At work, I have two 22” along with a nice mechanical keyboard (one that’s not too loud) and a giant steel series QCK mouse pad. We did a bit of gaming at work on my old projects.

What do you listen to while you work?

I listen to lots of stuff on Spotify and XM Radio. Typically I listen to alternative rock and sometimes go through phases of 90’s hip-hop and occasionally some top tracks from the 2000’s.

What’s your schedule like during build season?

Typically, I’d put in a

9 hour day at work and get off around 5 or 6PM. I’d start my robotics day around then and leave around 10PM during the weekdays During the weekends, we’d start around 10AM and

leave past midnight.

This usually gets pushed out further when we have deadlines to meet. It’s a

really intense schedule, but it’s what’s needed to ensure that our team builds

a quality machine. I typically wear many hats on the team including working on

software, mechanical design and fabrication with our students.

9 hour day at work and get off around 5 or 6PM. I’d start my robotics day around then and leave around 10PM during the weekdays During the weekends, we’d start around 10AM and

leave past midnight.

This usually gets pushed out further when we have deadlines to meet. It’s a

really intense schedule, but it’s what’s needed to ensure that our team builds

a quality machine. I typically wear many hats on the team including working on

software, mechanical design and fabrication with our students.

What everyday thing are you better at than anyone else?

Keeping my hands clean. I have a bit of a problem.

What’s the best advice you’ve ever received?

“Do what you love”. It’s worked out for me pretty well.

What is your favorite guilty pleasure?

I love soda…. And lots of it… Specifically, Mr. Pibb

Fill in the blank. I’d love to see ________ answer these same questions.

Travis Covington from 254. He’s the mentor that worked with me as a student and continues to inspire me to this day.

Anything else you want people to know about you?