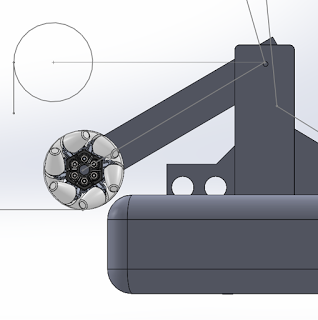

Before we build a prototype for an over the bumper intake roller we will actually do the 2D CAD and parts of the 3D design to make sure we are actually building something that will fit on our robot. We know that spinning wheels will suck balls in to our robot. What we actually need to test is how much compression should we have, which wheels will do it best, what is the spacing on those wheels. So by doing more design work early and build better prototypes we can find solutions to these questions faster.

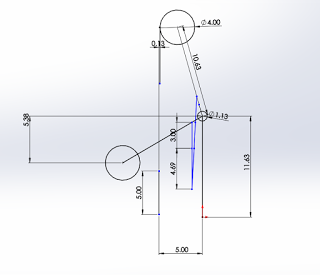

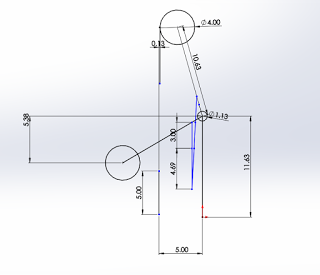

Here is a sketch of the over the bumper intake that we will be assembling tomorrow. This is designed in the same manner that Adam Heard and team 973 describe in their awesome RAMP Video series. This graphic give most of the information we need to actually build the intake. We know how long the pivot arm is, we know it’s up and down location, we know the location of the pivot relative to the front of the robot and to the floor. We know where to mount the pneumatic cylinder to move it up and down. This will use a 3″ stroke 3/4″ bore pneumatic cylinder.

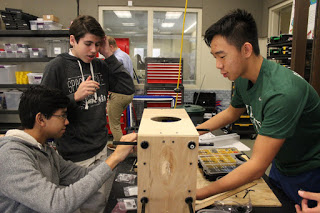

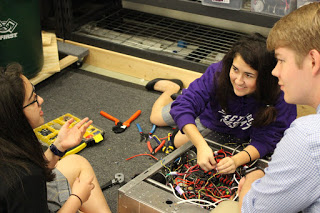

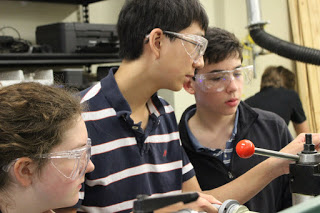

Several members are getting their first taste of machining during build season as well.

“But in fact, great projects, like great careers and relationships that last, are gardens. They are tended, they shift, they grow. They endure over time, gaining a personality and reflecting their environment. When something dies or fades away, we prune, replant and grow again.” – Seth Godin

Source: Spectrum