Intake Testing

Yesterday we were able to get some very basic driven intake testing done. We are very pleased with the results with just the basic printed diverters for centering.

Worn note

Newer note

Launcher Testing

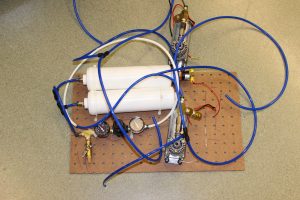

We were able to build a new launcher prototype based on information we’ve gathered from a few other teams and the data in 95’s build blog here and here.

Here is the breakdown of the launcher

-

6 Shaft, 2in Wheel Launcher

-

2x Falcons with 36t pulleys and 18t on the rollers for 1:2 up gearing. Both motors are driving all 6 rollers. Most of the shots were done at 3.5k to 4.5k motor RPM (double for shaft RPM), Velocity is PID-controlled in these tests.

-

Roller shafts 2.136” C-C, 40t belt distance for 18t to 18t pulleys

-

Top and bottom rollers are spaced vertically 3.6” C-C to allow for 72t to 72t gear spacing.

-

Printed pulleys everywhere which end up causing some problems and stopping testing for the night. (we rubbed the teeth fully off two pulleys)

-

Wheels are mostly just what we had on hand.

-

Black and grey wheels are 2 in AndyMark Stealth Wheels

-

White wheels are 2in Fairlane Wheels 35A Nitrile with 3D printed hubs pressed in.

-

Orange Wheels are 1.5” Banebots wheels, we don’t think they do anything but maybe stop the note from flopping around. Gap between them and the roller below is 2.1” so they shouldn’t be doing much.

-

Each set of wheels is approximately 2” wide, so we are only contacting the note at it’s edges.

-

The plywood plate for feeding is intentionally spaced away from the first set of rollers to allow the note to more naturally flow into the compression between the wheels.

One of the melted thru pulleys

Source: Spectrum