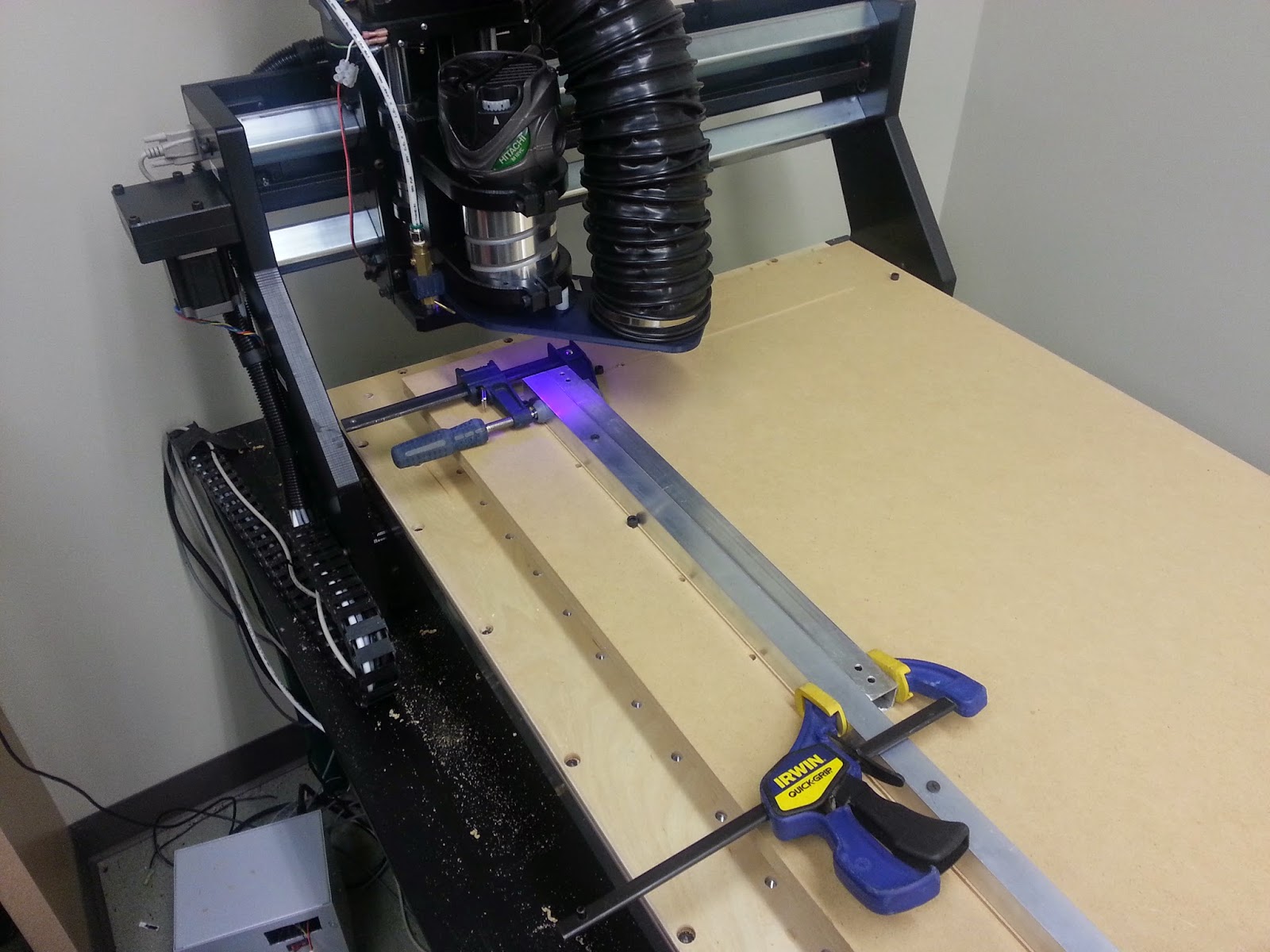

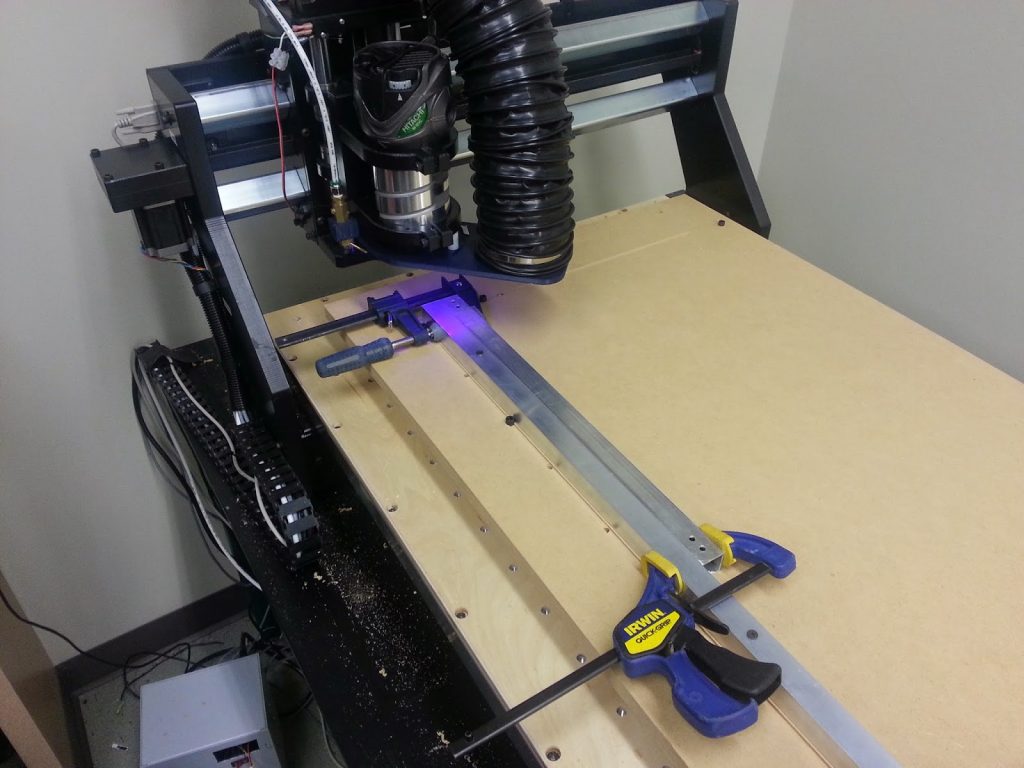

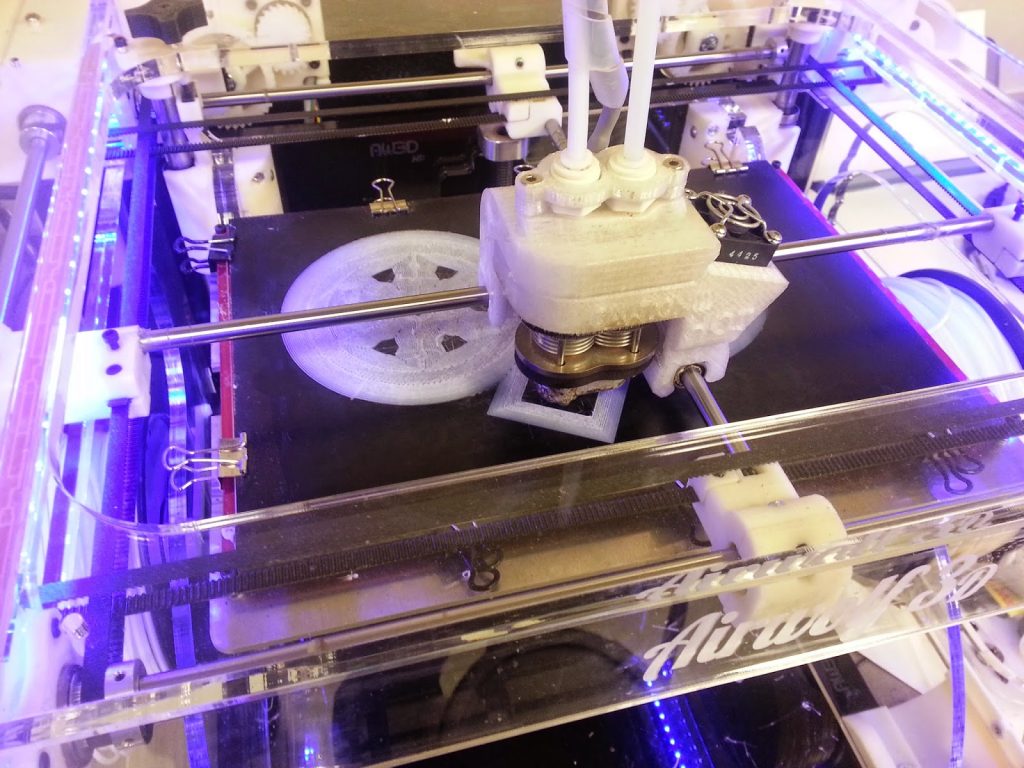

As part of our move to our new lab, we got a CNC router and new 3D printer. Today we had them hard at work. We setup the router to put 1in on center holes in our 2×1 rectangular tubing to make ourselves some prototype versaframe pieces. The photo below shows our test setup into a piece of scrap 1×1 tubing. The long piece on the right is part of a clamping jig that ensure we clamp each piece perfectly square. One of our team members wrought some useful g-code that allows us to easily tell the router how many holes we want, where to start the pattern, etc. This will make working with the extrusion much easier.

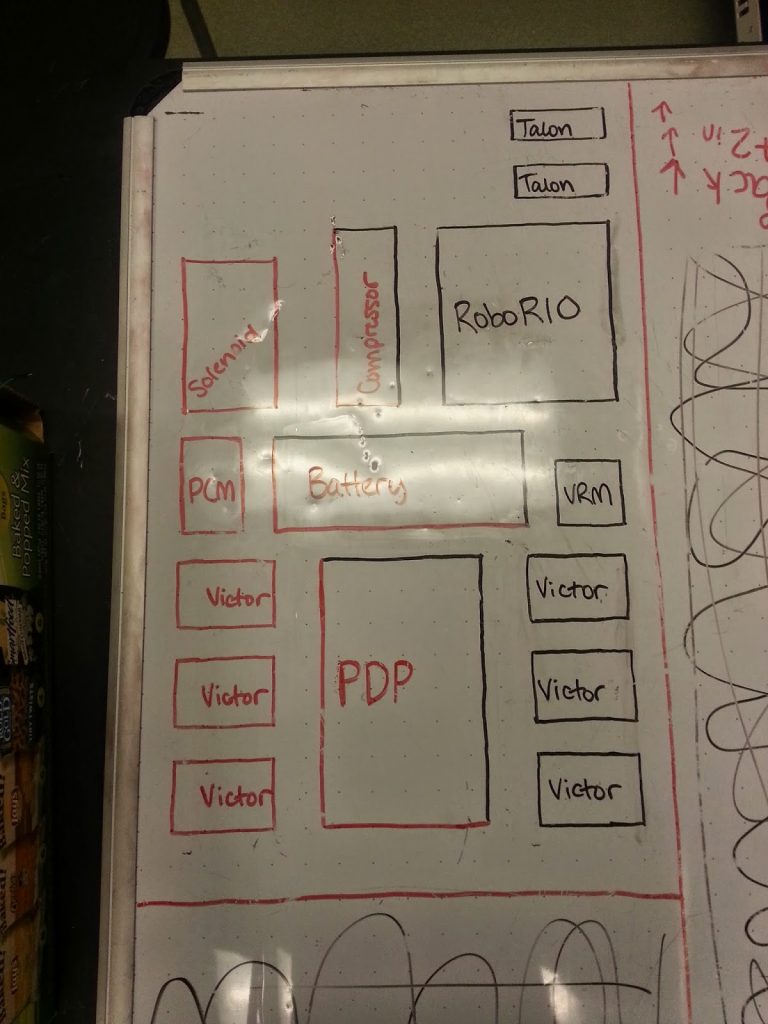

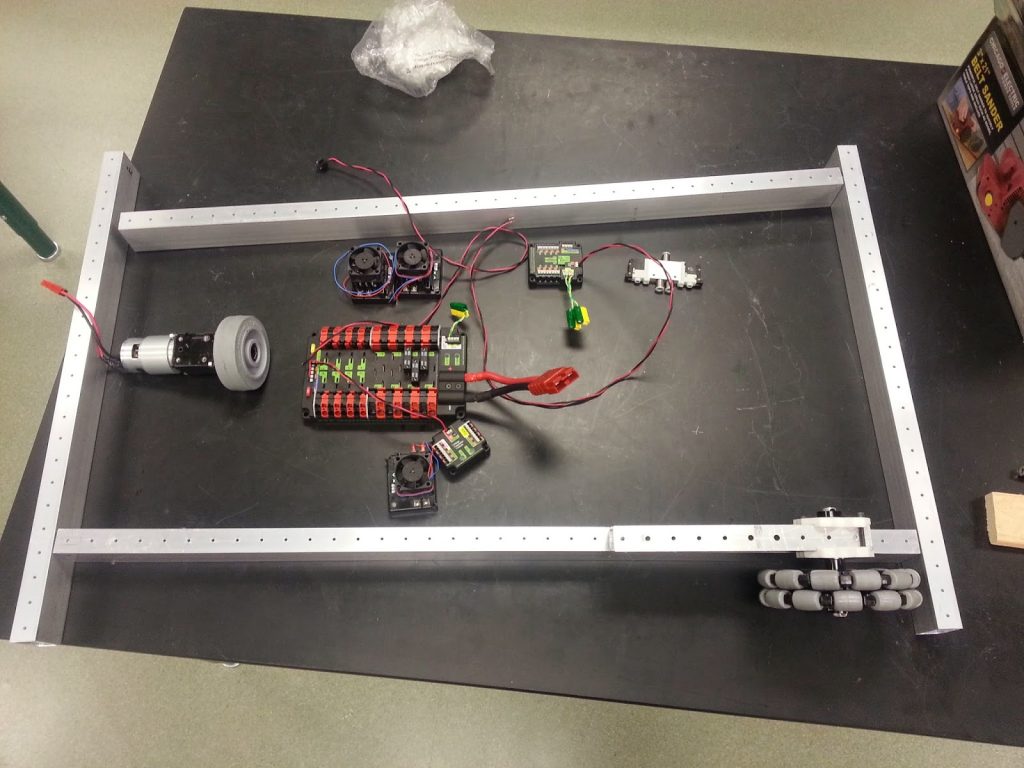

We are getting our drive train parts in tomorrow and we should be able to be moving on Saturday at the latest. This drive train will be our prototype robot, it will get lots of holes drilled in it in random places and we’ll tweak things before assembly starts on the real robot.

– Spectrum

“Live daringly, boldly, fearlessly. Taste the relish to be found in competition – in having put forth the best within you.” – Henry J. Kaiser