We experimented with 3d printing 5mm HTD timing belts.

CAD files

OnShape link to the belt generator we are using to make our belt models: https://cad.onshape.com/documents/0b9fe420322fe41da56645bf/w/76fedf9bfb5b78e06920c37c/e/7f7fe2c94f4c984c8a5860c6

We need to be able to tune the geometry of the belt to allow us to print it correctly and work well with our slicer settings (details below)

Materials

-

TPU 95A: This material was too elastic and stretched too much.

-

PCTPE: This is one of the most promising materials. It’s a nylon and TPU copolymer. It’s flexible but not very elastic. Belts made with this at the correct size could slip due to stretch, but we believe there may be a way to print belts slightly undersized that will stretch to the correct size.

-

TPU-CF: TPU with chopped carbon fiber this material also worked very well.

Slicer Settings

-

This was the important part of making timing belts that worked the way we wanted.

-

The main principle is getting each layer to only be complete loops of filament. In our case, this is 4 total perimeters of 0.6mm thick extrusions. You can adjust the model to help get the correct setup.

-

The top and bottom solid layers are turned off.

-

Avoid Crossing perimeters is turned on to limit stringing

-

The seam position is set to random to avoid a misshapen tooth where the seam may be.

-

This does leave a small hole in the belt, but that didn’t seem to cause a problem with our tests.

Results and Recommendations

-

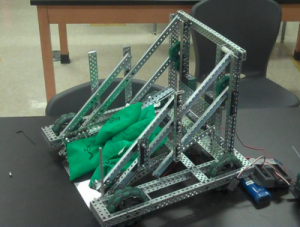

We printed two belts for our 2022 launcher hood and were able to launch balls well with the printed belts. They do feel looser than the stock-reinforced belts.

-

At the current stage, we are confident we could print a belt for a prototype or test, but we wouldn’t want to use a printed belt on a competition robot in any critical area.

-

The next step is to alter the geometry so that we can easily print a belt with a slightly smaller diameter than a standard belt but with a similar tooth size so that we can account for the stretch built into the printed materials.

Source: Spectrum