We have been working on creating a system to allow us to quickly and easily design mechanisms that let us solve the problems given to us in the FIRST Robotics Competition. This past season our prototypes worked well but they took a long time to modify and adjust and that led to our design process taking more time than we would want.

We listed some goals for the system.

Goals

- Rapid iteration

- Easy to remove and add parts

- Easy to reuse parts in the next prototype if needed

- Inexpensive

- Try to avoid using expensive parts such as bearings, etc.

- Use a cheap base material that is locally available

- Easy adjustment

- Clamp systems for small adjustments of spacing and belt and chain tensioning

- As few unique parts as possible in the generic system

- Easy to make custom parts for each unique application if needed.

- Able to quickly make rotating parts such as intakes, ball paths, etc.

- Powered by a hand drill or by a Versaplanetary (or 57 Sport if you like)

- Able to quickly attach to pneumatic cylinders for making wrists, small arms, catapults, etc.

- Able to make a rough linear slide system for prototyping stackers / elevators (2015)

Basic System Explanation

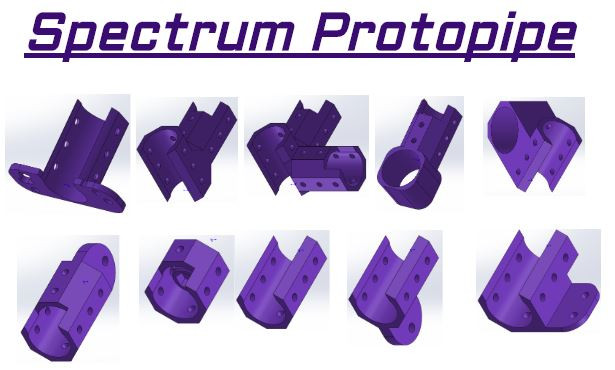

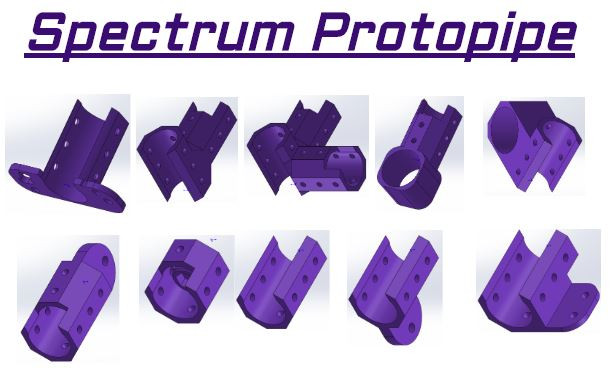

We decided on using 1/2″ PVC pipe and 3D printed connectors. 1/2″ PVC is widely available at most home improvement stores for very little cost (a few dollars for 10 ft lengths). 3D printers are becoming very common among FRC teams and the filament is getting much cheaper as well ( <$20 / kilogram). So these parts seem like they would work well.

The connectors allow you to connect the pipe to flat parts as well as hold 1.125″ bearings for making systems with hex shafts, etc. To connect the pipes to the connectors you can either use short self-drilling screws or hose clamps to clamp them on. The clamps allow you to easily adjust certain parts to move items and figure out the best measurements for your system.

The full system is described in the google doc explanation here.

Link: Full System Explanation, Examples, and Notes

CAD Files

We have uploaded all of the Solidworks part files, STLs, and STEP files for the different parts as well as a few STEP files of the example prototype/bench tests that we have designed.

Link: CAD Files

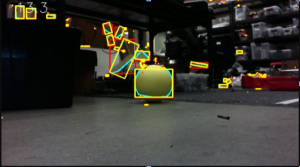

Examples of the System

Source: Spectrum