Here is the the video from our Butterfly drive test. This looks really good and is just a lot of fun to drive. If the omnidirectional drive doesn’t work out we will very quickly switch back to butterfly.

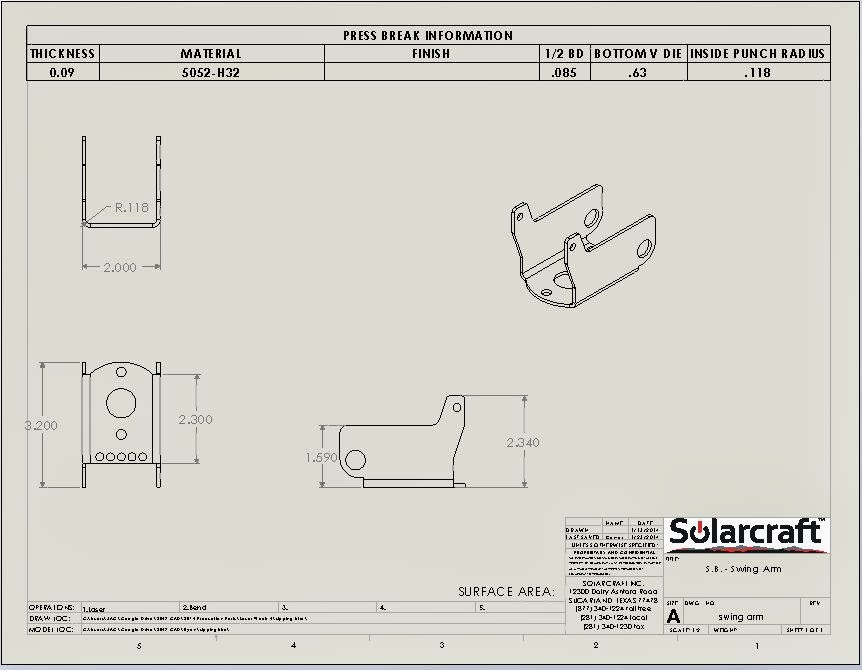

We finished up the drawings for our launcher and our collector. Every part that we cut at Solarcraft has to have a drawing that goes with it so that you know how to bend the part after it has been cut. Here is what one of the drawings looks like. They outline how long the flanges are on the sheet metal so that we can program the press to bend the part at exactly the right spot.

Another very important system was prototyped today: handles. We got this idea from team 610 in this CD post. All it takes is some steel cable, a couple cable crimps, and pneumatic tubing. A lot teams probably already have this stuff in their shop. Crimp a loop in the cable then slide over the tubing and crimp a loop in the other end. Rivet/bolt this to your chassis and now you have convenient light handles that can just fold into your frame perimeter. This should work really well on the AM14U Chassis, put one bolt on the outside plate and one on the inside plate. Make one for each corner of your robot. Your drive team will thank you a lot for having handles, and you lower the risk of someone doping your robot.

Speaking of team 610, one of their students, Ryan Tam, put together an awesome design tutorial and parts library. If you ever wondered how the World Champions train their team to design high-quality, reliable robots, now’s your chance to find out. We highly recommend taking some time to read over this; our team will be using this to help train new members in the future.

– Spectrum

“You can’t use up creativity. The more you use, the more you have.” – Maya Angelou