Intake Testing

We had some of our best intake tests today. One of the key points in an interactive design cycle is when you begin to understand what can be removed not just what can be added to allow the system to keep working but to make it simpler and more robust.

Yesterday Alpha’s intake had 3” compliant wheels on the top roller and launcher. Today we swapped those for 2” polycarb and silicone rubber (these are the hood rollers from our 2022 practice robot).

This test setup worked very well and allows us to build the intake lighter, simpler, and make it less expensive. This is just today’s version of the intake, we expect it will change many times over the season and probably before next week but it’s at a good progress point.

The current intake can

-

Intake cubes from the floor in the full down position.

-

Intake tipped-over cones from the floor when the nose is slightly pointed at the intake and the flange is inside the width of the intake. We estimate we have around 150 degrees of intake range on the cone. With training, we believe this should be good enough for our pilot to use this as an efficient loading option from the loading zone.

-

Intake standing cones if the intake/four bar are set to the correct height. The current intake is pretty height sensitive to standing cones. We need to be within in about a ¾” height window for it to intake well. This should be good enough for us to intake cones from the Human player shelf.

Things to experiment with

-

Intake from the single substation?

-

Improve storage geometry to make sure the cone tip always goes in the intake so we aren’t holding cones tilted up.

-

Ensure our grip on the cones is firm enough so we never drop a game piece.

-

Improve scoring geometry on high and mid posts.

Intake Standing and Tipped Over Cone

Intake Cube

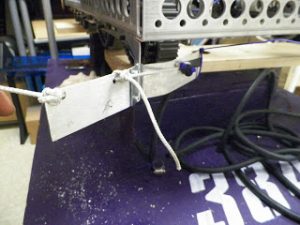

1/25/2023 Intake Specs

-

Lower roller is just 1/2″ hex with silicone tube floated on top.

-

Top roller is a 2″ polycarb with silicone tube floated on it around it (actually, it’s just our practice bot hood roller from last season).

-

Gap between the roller surfaces is around 4.75″ in these tests and roller C-C is at a 73° angle from the floor.

Elevator Progress

We cut all of our elevator rails for the practice robot and competition robot. We also began laser cutting some of the additional parts.

WCP Inline Clamping bearing blocks are being powder coated, as are The Thrify Bot Elevator Gussets we will be using on the elevators.

Source: Spectrum