3D printing

We have our print farm running a lot of production parts for the 3 robots (PM, FM, & Photon). Here are some of the timelapses from the Bambu X1C.

Intake Gears+Pulleys

https://photos.smugmug.com/2024-FRC/Build-Season/Week-5-2024/i-HRkDPS9/0/0ae070c6/1280/video_2024-02-09_21-42-06-1280.mp4

1.25” OD Roller Pulleys

Elevator Top Frame Support

Laser Cutting

This is our laser cutting a test part of the launcher sector gear so we can test the fit. We manually adjusted the teeth size to remove some of the backlash in this gear.

CNC Router

It’s hard to get a good video through the chip curtains but this is our router cutting some of the climber+elevator gussets.

(It’s a loud video)

Tapping Station

This is a video I made a couple of weeks ago to show someone how the tapping station we purchased in the fall works. It’s pneumatically powered and has a lever to turn it on and a button for reverse. It has made tapping shafts so much faster and we’ve used that to design a lot of standoff into this year’s robot.

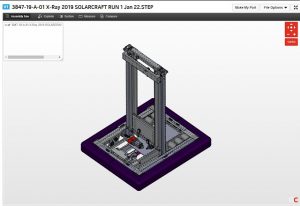

Test Fitting Controls

We started test-fitting our electronics layout. Our general plan is to leave as much of the belly pan open as possible for electronics and then just fit them where they make the most sense. Nearly everything is held down by VHB or foam mounting.

Source: Spectrum