We actually didn’t meet for the first time in recent memory. The roads were iced and we have a deep freeze for over 24 hrs which rarely happens in Houston.

Since we can’t work on our prototypes, we wrote out our entire current robot plan also their is some updated CAD of the virtual 4 bar intake at the end.

Robot Plan

Drive train and base

– 28.5″ long by 24.5″ wide

– 4 wheel drive, 6″ omnis

– 2″+ ground clearance, it won’t be great over the corner but shouldn’t get stuck. Should be fine up the platform.

– Not great up steep ramps but steep ramps are bad anyway. Arm may help us out of weird end game situations, forcing it in to the ground, etc.

– current plan is to go with a sheet metal inverted west coast drive (cantilevered wheels on the inside, like 118 last year) to get us a bigger belly pan. 24″ is small, our normal wheel wells wouldn’t leave us much room and vertical electronics are annoying.

– small size let’s us drive under the scale when needed and through the null territory without getting in the way of a partner scoring on the scale. (Also drive under opponents scale if you want to risk it)

– Small size makes it easier for us to get on to tailgates (lifting platforms)

– omnis makes it real hard for us to tip sideways, arm can right us if we tip forward or backward, hopefully we don’t need to do that ever.

– 6 miniCIM drive train

– balls shifters

– 5-7 low, 14-16 high gear, need the high gear for portal cycles.(those aren’t set and will probably change as we run the numbers better)

– a frame for the arm also acts as frame members

Arm

– pink style arm

– single big rotation joint (about 28″ from the ground)

– single telescoping extension

– all sheet metal, all bearings for extension.

– 3x 775pro on the arm with a disk brake so we aren’t stalling the motors much. Gearing allows us to curl for the climb when we aren’t lifting a partner.

– 1 or 2 775s on the extension, not climbing with the telescoping stage, just hanging from it (has to be able to hold the wait of the robot but not lift it)

Intake

– able to intake from both sides of the robot when the arm flips over

– still prototyping our final solution but worst case it’s some version of a sideswipe intake (1114 2015). We want to get the virtual 4 bar intake(look below for a CAD sketch) working but it’s definitely more complicated but it should let us intake 11″ cubes easier.

– Every cube in this game matters and time wasted trying to turn cubes is time not spent score. Drivers may be able to just approach cubes from a different angle to avoid the 11″ face but probably not everytime.

– intake is 2x 775pros, one for each side so we can spin the wheels at different speeds to help with I taking.

– wheels should be able to launch cubes 2-3′ for pushing them up to the scale (arm will rest them on the side of the scale for up tilted scales). May include a pneumatic punch if we need more height/distance.

– intake opens and closes with pneumatics, let’s us drop cubes and place them nicely.

Climbing

– hooks hard mounted to the arm extension. One on each side we can grab the square tubing from either attack direction.

– hooks fold out or extend to give us more reach for the bar then we get from the single extension.

– solo climb is a curl. That way we can climb second and as long as we can reach the rung we can curl away from the already hanging robot and both get points.

– dual climb is a forklift tailgate that folds out the front of robot, forks are stored along the a-frame for the arm.

– winch is attached to the tailgate so we can get our winch pull location as close to our partner as possible so our climb doesn’t lean as much.

– forks have tread or other traction on them so robots don’t slide off

– forks have ramps on the sides of them so teams can drive over them.

– some type of retaining bar goes over the partner so they can’t tilt off, this won’t need to actually tighten to their robot, just prevent them from tipping up.

-winch cable gets mounted to the same hooks we use for the solo climb, as we winch up the arm is back driven to allow us to get it height.

– winch is 2x 775pros

– tailgate and winch can be detached easily match to match, so we can be lighter when we don’t need it.

Strategy

– own our switch and the opponents switch as fast as possible and maintain the lead.

– run cycles from portals to op switch and to the scale.

– climb around partners if needed, lift a partner if that’s needed as well

– able to pull from the cube zone without knocking to many cubes out of the zone

-able to quickly grab cubes our opponents knock out of their cube zone.

– have third partner maintain your own switch lead and score at least 3 cubes in the vault.

-scoring on switches under defense will be hard since you have to get your bumpers touching the fence to be able to score (reasonably). Lots of spin moves.

1. Score in op switch and the scale, defend them from scoring in their switch.

2. Score in the Scale and your switch

3. Score in your switch and vault, defend your switch

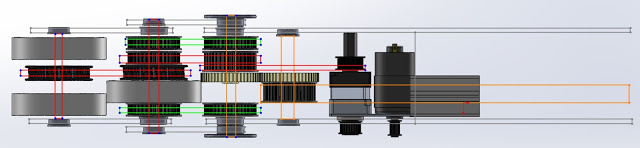

Intake CAD

“Friends share all things.” – Pythagoras

Source: Spectrum