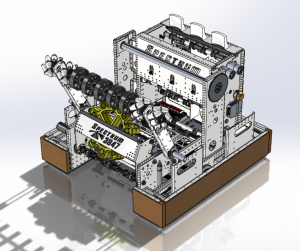

Progress Report

The team spent the majority of their time in the lab today tuning their subsystem designs.

Sheet Metal Deadline

The subsystems that require sheet metal are really trying to meet next week’s deadline and are hammering out the last big chunks of the design before lightening.

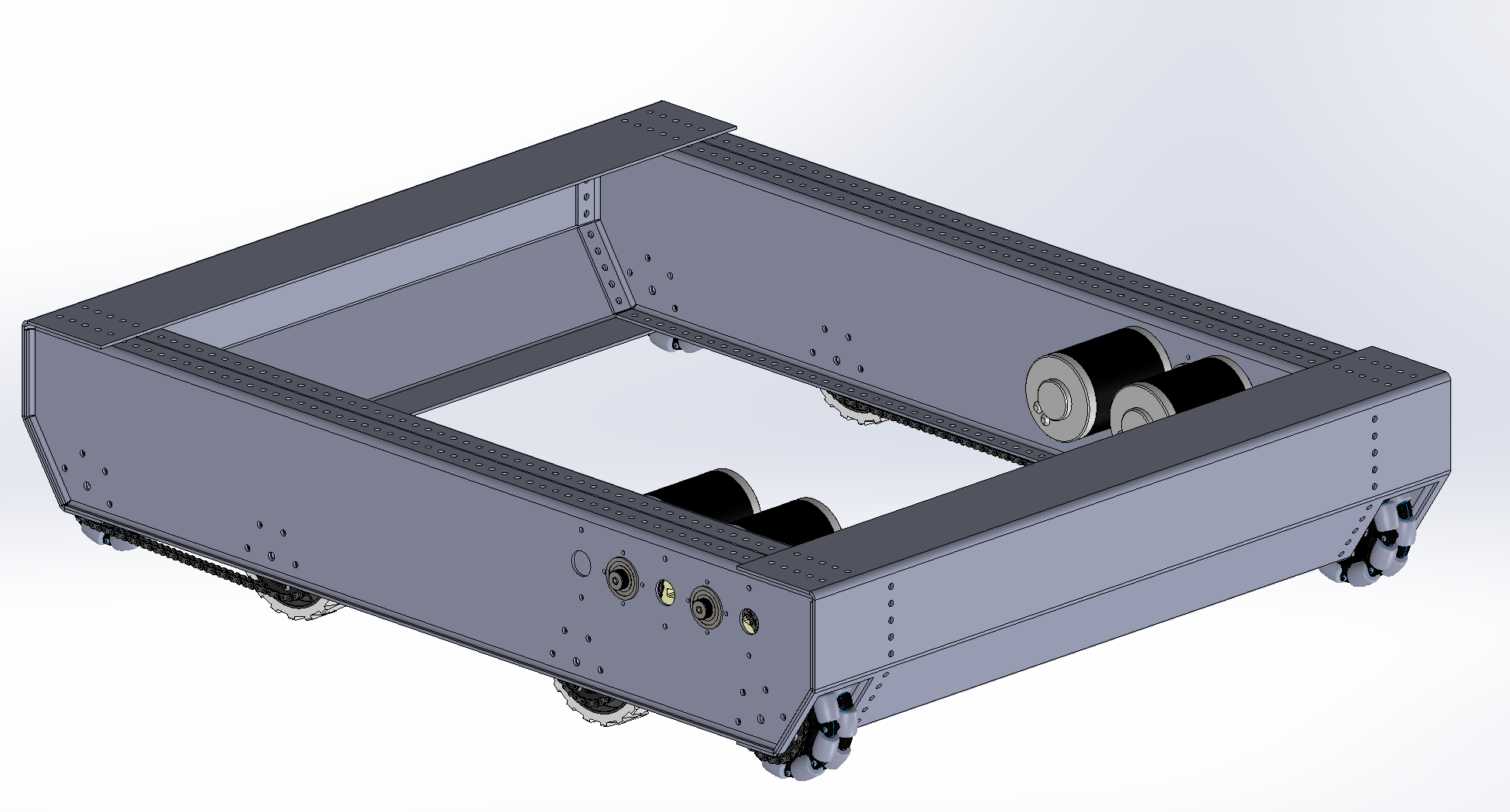

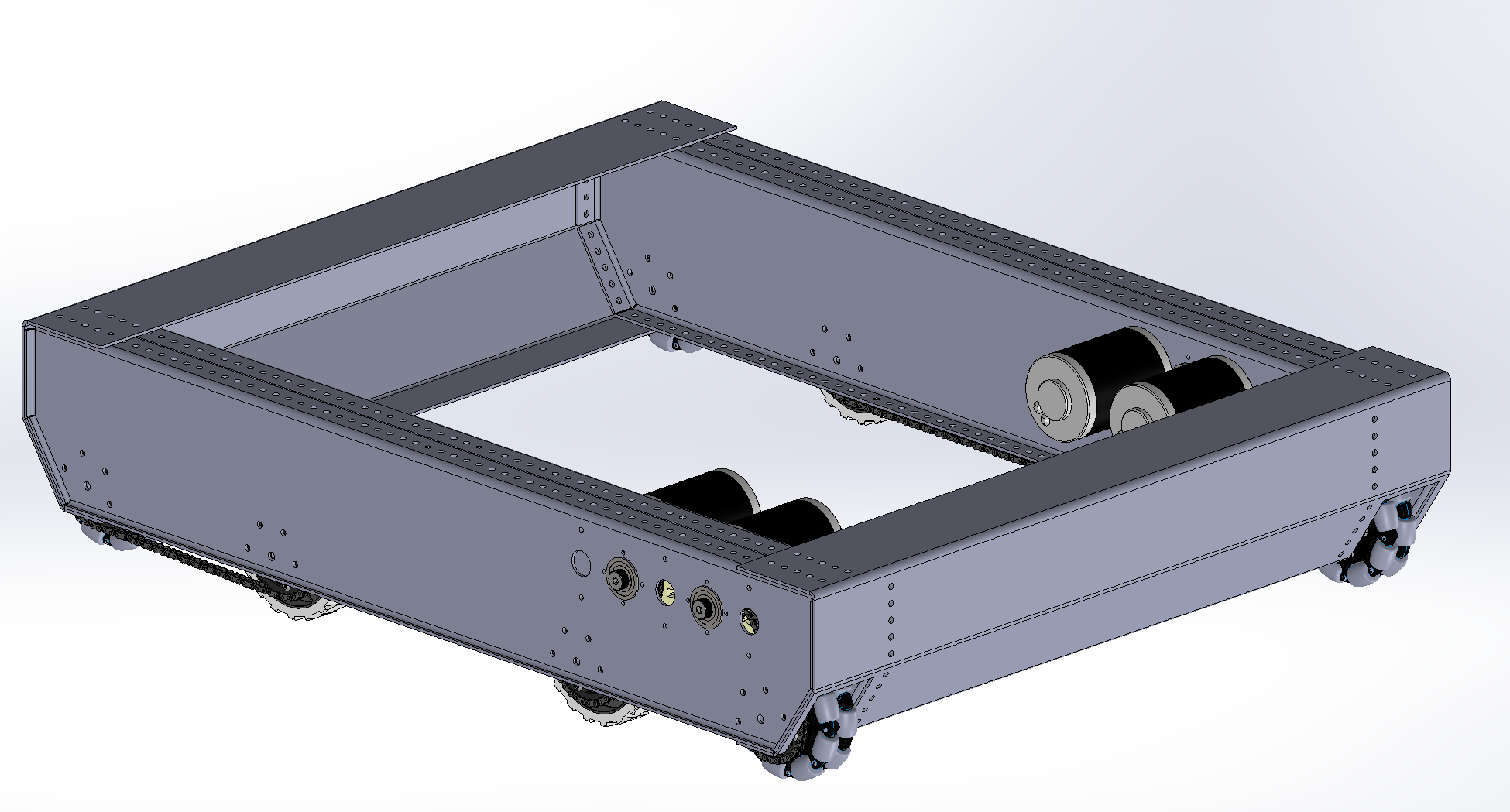

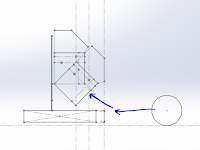

- Drivetrain

- Access and mounting holes have been added, and the encoder mount is underway

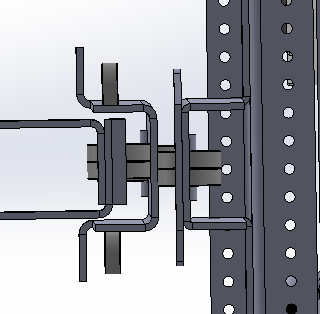

- Elevator

- The carriage is starting to come together. Bearings have been added to the side rails of the elevator as well as being sandwiched in between the plates on the carriage.

Intake

- Cargo Intake Box

- Part of today was also focused on intake geometry. The cargo box carries the ball to different positions on the elevator without obstructing the hatch mechanism.

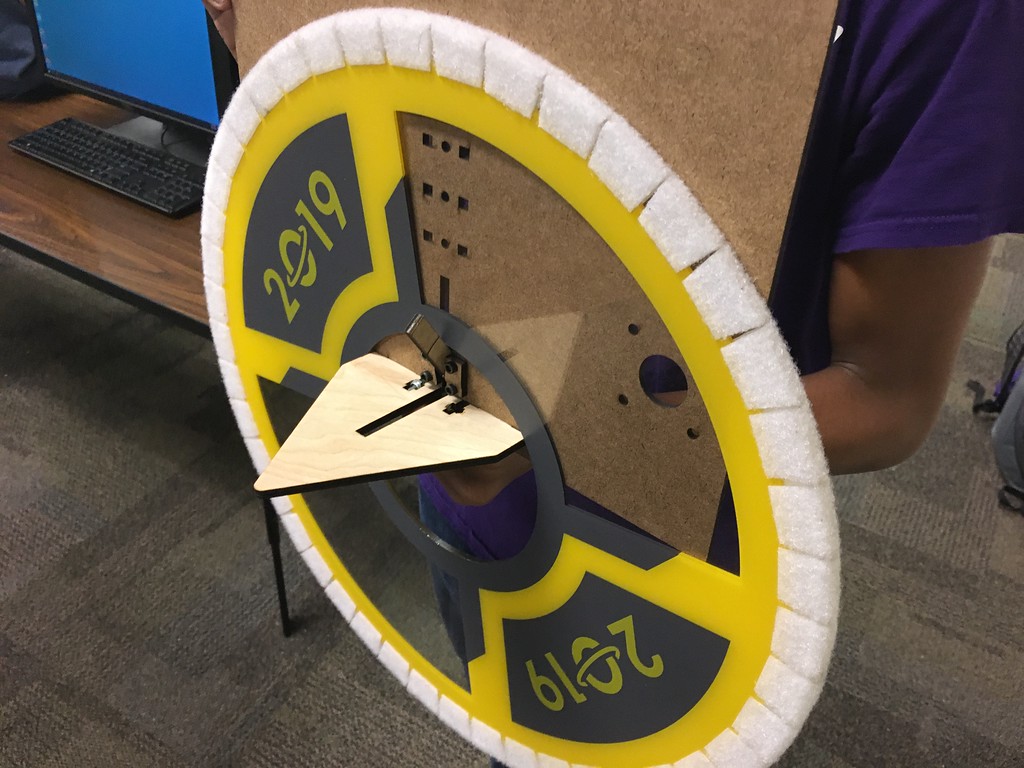

- Hatch Subsystem Version 2

- The hatch intake has undergone an upgrade, including a new feature. While still in the prototyping stage, we had implemented a ‘finger,’ a 1/4″ thick piece of Lexan placed above the (duck!) beak. A pneumatic cylinder actuates the finger and allows it to grab and secure that hatch so that any jostles by other robots do not impede the hatch from reaching the intended deployment zone.

Allenless Again…

The team has divided into two warring tribes who are battling for control over the name of the 2019 robot. Not really, but in all seriousness, we are diligently working while we await Allen’s return from the blizzards of the north tomorrow morning.

– Spectrum

“There is no substitute for hard work” – Thomas A. Edison

Source: Spectrum