Ball Sizing Rings

We laser cut 3 ball sizing rings, 12.5″, 13″, and 13.5″ in diameter. This lets us inflate balls to the various levels inside the tolerance range so that we can practice with the different inflation pressures. Balls at 12.5″ and 13.5″ behave differently in several aspects that we have noticed so during our interactions.

- Green = Go = Inflate More

- Yellow = Slow Down = You can stop inflating

- Red = STOP = You’ve inflated too much.

Design Reviews

We have decided to start doing design reviews every Tuesday (this week was Wednesday since we didn’t have school yesterday).

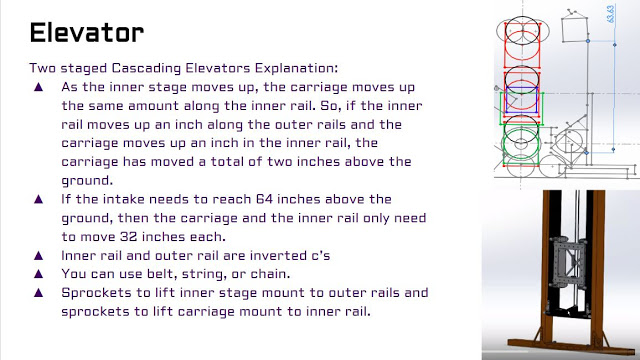

Each subsystem team is responsible for making a few slides about their design and progress and presenting to the team. Here is an example slide from the elevator subsystem team.

The current subsystem list includes

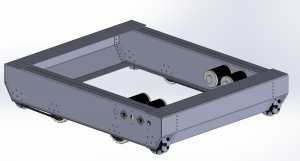

- Drivetrain

- 8 – 4 in wheels

- 4 traction, 4 omnis

- 6 MiniCIM drive (may be NEO after evaluation)

- Approximately 12fps(JVN adjusted speed)

- Elevator

- cascading #25 chain elevator

- Intake

- floor cargo intake

- floating top roller

- Linear slide deployment to not interfere with the lvl 1 rocket scoring.

- Constant force springs used to tension it down

- Cargo Mechanism

- elevator cargo mechanism

- simple roller and dustpan design)

- Hatch Mechanism

- velcro and alignment device + pneumatics to deploy

- alignment device may be actuated if we think velcro is going to degrade too much

- Climber

- 4 Bar motorcycle lift style climbing mechanism.

- Programming

- Electronics

- MCC (we are designing and building an MCC for practice)

- Simple velcro+pneumatic hatch mechanism for lvl 1 hatches

- Single jointed arm with cargo intake that can floor collect and score in rocket levels 1 and 2 and the cargo ship bays.

All of this is still subject to change, but we have flushed out more of our design in the first 5 days then we have ever done before.

– Spectrum

“In preparing for battle I have always found that plans are useless, but planning is indispensable.” – Dwight D. Eisenhower

Source: Spectrum